A sneek peek into the process of making a custom made Fountain…

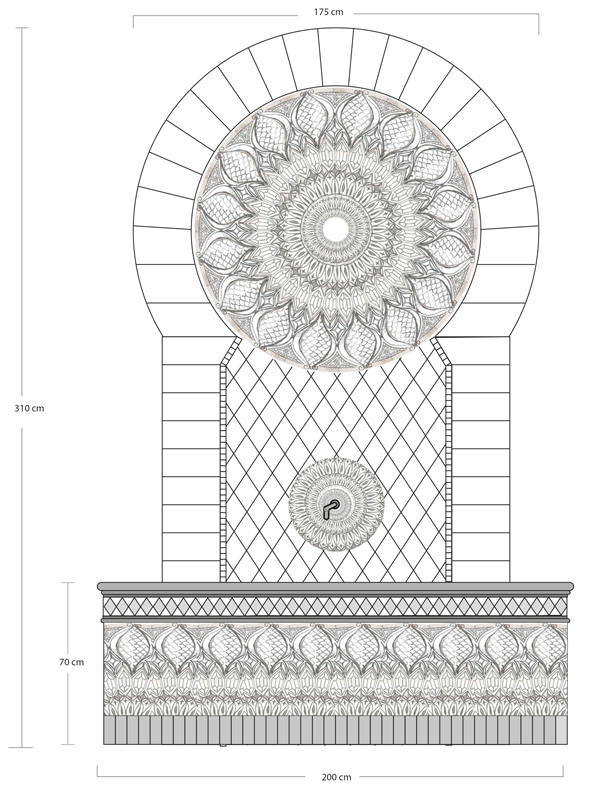

1. Firstly of course is a sketch and a happy client...

2. The process begins. This ceramic fountain measured a whopping 2 x 3 metres and there are lots of pieces to the puzzle. Each piece needs to fit together perfectly (sweat) but thats our speciality! It is impossible to try and explain the vast amount of precision, detail and time that is required but here are a few images of the making…

3. When all the pieces fit together, the tiles are fired for the first time in the kiln. We then make colour samples and more colour samples and then the glazing starts and it is fired for the second time. We then start placing it together again to see if everything is working as it should! Many pieces are numbered on the back like a giant jigsaw puzzle.

4. These photos show the long installation process and they did an amazing job :)